Optimize With Digital Twin Technology

Optimize With Digital Twin TechnologyAs the commercial buildings that emptied at the beginning of the pandemic are beginning to fill again, facility management looks much different than it did in December 2019. While facility managers are still focused on maintaining buildings in the most efficient ways possible, they have new challenges and priorities. In addition to implementing a digital transformation strategy and execution for improved sustainability, occupant comfort, productivity, and physical-logical security, they need to adopt post-quarantine protocols that prioritize indoor air quality, space utilization, people tracking, and contact tracing.

Optimize With Digital Twin TechnologyAs the commercial buildings that emptied at the beginning of the pandemic are beginning to fill again, facility management looks much different than it did in December 2019. While facility managers are still focused on maintaining buildings in the most efficient ways possible, they have new challenges and priorities. In addition to implementing a digital transformation strategy and execution for improved sustainability, occupant comfort, productivity, and physical-logical security, they need to adopt post-quarantine protocols that prioritize indoor air quality, space utilization, people tracking, and contact tracing.While the digital transformation of commercial buildings has made it easier to track and control building events, connected buildings generate a lot of data. Analyzing it all to make decisions that matter can be overwhelming. In response, many facility managers are turning to the latest digital twin technology to help them manage their new confluence of priorities and make their buildings smarter, healthier, and more sustainable.

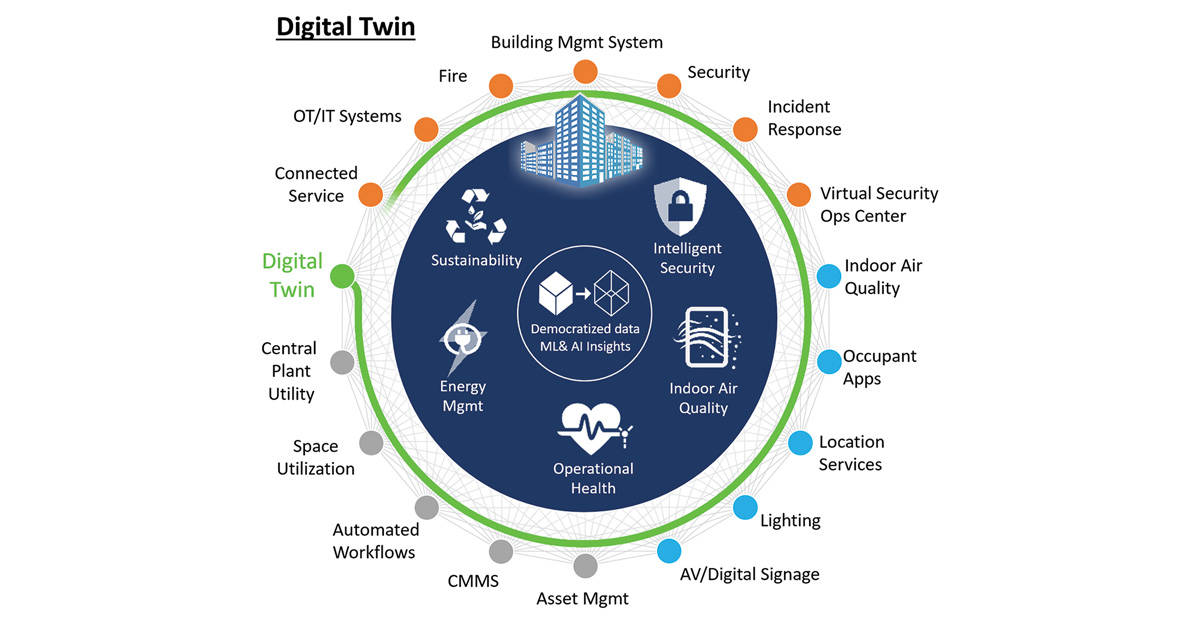

A digital twin offers a common framework that unites discrete data streams to create a holistic view of the building and its life cycle. Through increased data fidelity, democratized data, and machine learning and artificial intelligence insights, it can help facility managers improve key KPIs and achieve performance goals. (Source: Johnson Controls)

Building an intelligent digital twin. A digital twin is a connected, virtual replica of a physical product, asset, or system. Think of it as a digital thread that stitches together contextual relationships across the as-built environment. For commercial buildings, the digital twin’s most important attributes shape these relationships, which are the building and its spaces, assets, events, and people.

Achieving a successful digital twin also relies on two pillars. Through data and visualization, a digital twin connects and integrates all building systems into one unified application.

Data is what digital twins are built upon. A digital twin is not just a twin of the building but also a digital representation of every asset within its spaces. Assets can be an HVAC system or access control and video system, or they can be the connected internet of things (IoT) equipment that’s part of those systems, including thermostats, cameras, and IAQ sensors.

These edge IoT sensors continuously record data streams that feed asset systems, which the digital twin replicates and simulates. The digital twin offers a common framework that stitches these data streams together to produce a holistic view of the building and its life cycle. As it collects data over time, the value of the digital twin builds upon itself.

The holistic view a digital twin provides is presented through visualization, which allows facility managers and other stakeholders to see building health and sustainability metrics in a single pane of glass. Using machine learning and artificial intelligence, nuance alarms are filtered out leaving only prominent alarms and notifications so facility managers don’t get caught in a cacophony of data. They can quickly and confidently respond to high priority events and manage their workstreams with efficiency and accuracy.

Shifting from reactive to preventive management models. By processing and presenting data so clearly, digital twins make it possible for facility managers to move operations from reactive to preventive models that can drive decision-making. Using digital twin technology, they can reference historical states of the as-built environment and its assets, see the present state in real time, predict future states, and even simulate and test future processes and updates.

In real-world use, digital twins have been known to improve sustainability by 50%; optimization by 35%; productivity by 20%; and space utilization by 15%.

The possibilities of what a digital twin can do are endless. Investment can be incremental and isn’t about achieving every outcome at once. It’s about understanding which digital threads matter most right now, achieving one or two use cases to prove ROI, then gradually stitching in new digital use cases and capabilities. This naturally creates an operational network effect fueled by the digital twin.

Over time, those digital threads weave together into a fabric of intelligence, which are consumed by various stakeholders of the building. Eventually, the subsystems leverage the twin to make independent decisions with high fidelity and can self-heal by calling their own service when needed. A self-healing building can automate processes it has learned, freeing facility managers to focus on new, urgent priorities when they arise. With the help of incremental digital twin investment, buildings start to become self-healing and autonomous.

Making the first digital stitches. If a facility manager is just getting started, they can focus on one or two priorities that matter most and build the dimensions of the digital twin to meet outcomes today. Those priorities depend on building and occupant needs.

Today’s post-quarantine priorities include ensuring the air is as clean as possible, the HVAC and ventilation systems are functioning at peak performance, and spaces are effectively utilized. Digital twins can help predict air cooling, heating, and clean air flow based on occupancy and space utilization in real-time using occupant people-counting sensors.

Physical-logical security uses employee badge access to determine who is in the building. If an employee is physically in one building, the IT system should not allow the same person to log in from another location, thus enhancing cybersecurity. Having a digital record of people-counting sensors deployed can accurately identify which spaces are being utilized and which are under-utilized so the option of modification can be made to better enhance space utilization of meeting rooms, workplaces, common areas, labs, storage, and car parks.

If spaces aren’t being used, they don’t need to be heated or cooled in the same way as if there are people in them. Using digital twin technology, facility managers can recognize these trends and various pieces of equipment can be turned on only when needed, optimizing comfort based on occupancy and tracking clean air flow. The additional use of mobile comfort apps is becoming more common and provides a high degree of data fidelity beyond thermostat sensors alone. As most operational expense comes from energy use, this can help optimize consumption and can improve sustainability.

Weaving the digital fabric. The digital twin ecosystem includes other solutions that strengthen the twin’s capabilities. These include edge IoT, cloud to cloud integrations, and a partner ecosystem.

The edge IoT includes much of the sensorization, which provides the metadata for intelligence. This technology connects to and receives information from the plethora of sensors simultaneously monitoring asset performance throughout the building. By collecting and amalgamating sensor data, the edge IoT feeds events coming from sensors into the digital twin graph via a cloud component. This makes it possible to know what each asset is, where it is, what events are coming from it, and what state it’s in.

A partner ecosystem pulls these solutions together. Johnson Controls, for instance, works closely with technology partners, system integrators, and 3D BIM visualization companies like Autodesk, to bring context to data flowing throughout the system.

Flagship solutions such as the Johnson Controls OpenBlue Enterprise Manager (OBEM) enables facility managers to view a building’s energy, air quality, and occupant KPIs in a single pane of glass. Through a 3D BIM of the building, heat maps, and data-driven analytics, the digital twin visualization enhances OBEM features, providing greater context of alarms and notifications across building spaces, assets, and events, as well as a new dimension of context for making decisions.

The integration of these solutions makes it possible to capture and access real-time and historical data that can help facility managers optimize operations. Using the digital twin ecosystem, facility managers can simulate and model years into the future to achieve specific goals. Over time, the digital threads that have been stitched together weave a fabric of intelligence.

Moving from reactive to proactive self-healing. Facility managers can use this fabric of intelligence to create smarter buildings that respond to urgent events now and build data foundations for the autonomous, self-healing buildings of the future.

As its intelligence grows, the digital twin eventually becomes a decision engine that informs a facility manager without nuance alarm noise, allowing for more accurate predictions, recommendations, and quick action. This can strengthen and speed up decision-making, prevent failures, improve efficiency, and lower costs.

Systems themselves can start to communicate without human interaction and take on an autonomous mode. The systems will automatically make decisions and generate work orders when required. This allows facility managers to move from managing details to overseeing them. By taking on a review-and-approve role for automated processes, they are free to shift their expertise to other areas of critical priority.

A digital twin provides insights into the past, present, and future of a building environment so managers can ask “what-if” questions that improve decision-making. They help facility managers prepare for a future that’s ready for whatever arises; a future that’s smarter, self-healing, and more sustainable.

Pelski is director for Johnson Controls OpenBlue Digital Twin and Edge IoT platforms, responsible for driving strategy, product development, and partnerships across commercial, healthcare, and industrial verticals. Pelski is heavily focused on digital twin strategy and product development to reduce digital friction and democratize data across the healthy building, sustainability, and occupant experience segments. He is a steering committee member of the Digital Twin Consortium and digital twin evangelist speaker. He holds a B.S in Business Management, Management Information Systems from University of Wisconsin and an MBA from Florida Atlantic University.

https://www.civilengineering.ai/optimize-with-digital-twin-technology/

Post a Comment